MOULD

The most technically innovative and unique part of project RPSD is our open source mould, which is used to form the skateboard decks. Previously it did not exist, which means we can proudly say this is the first in the world of its kind to be released.

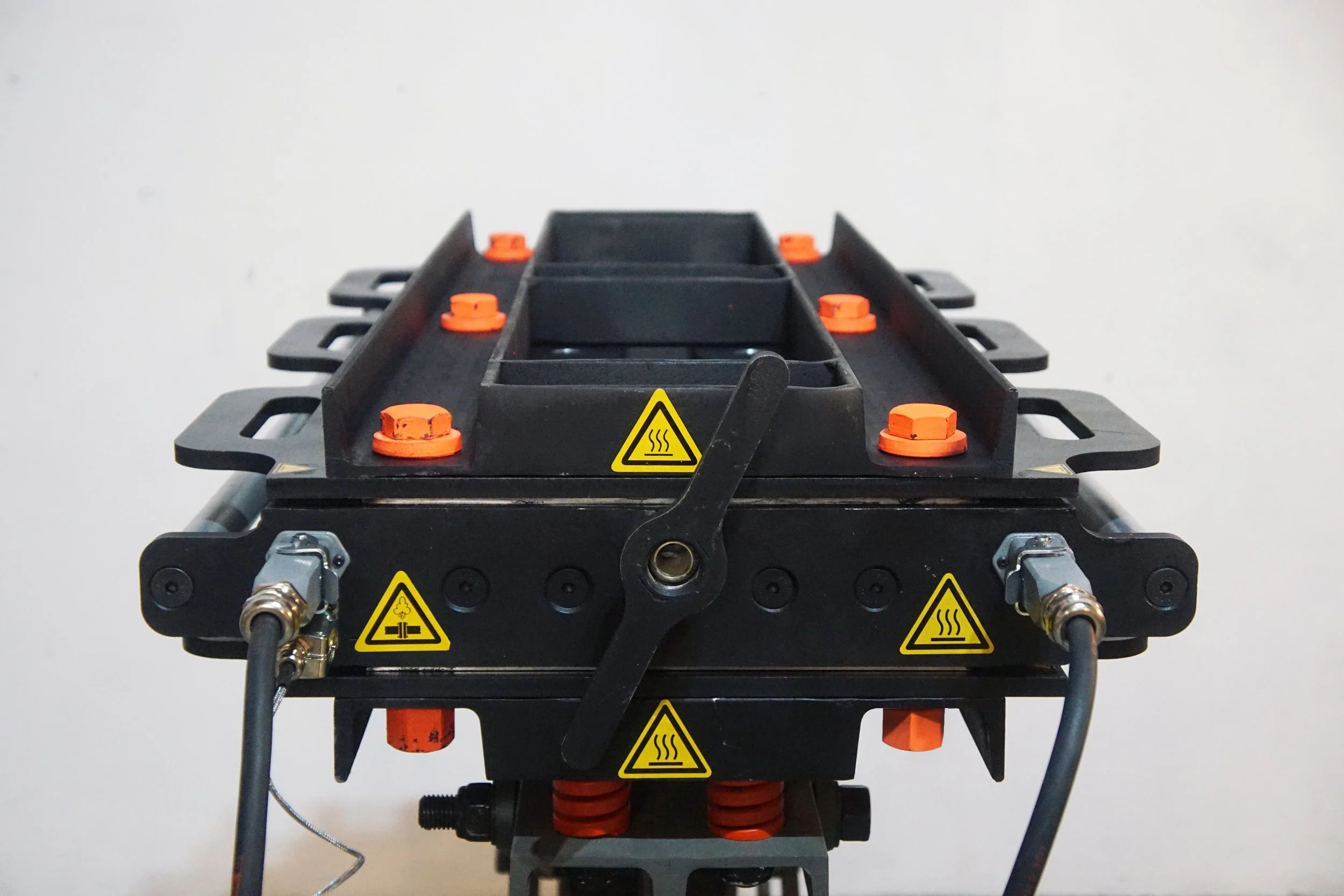

The mould consists of three CNC cut aluminium pieces that form the shape of the deck. The mould is electronically heated whilst molten plastic is injected into the mould using an extrusion machine. It also features an adjustable height table, a quick release handle and suspension for easy operation.

The mould is fully open source, all the information you need to make one yourself is completely free for you to download. Click the “BUILD” button below. Alternativley, if you would like us to build one for you, click the “BUY” button below.

TECHNICAL DATA

General

Model: RPSDMV3

Version: 3.0

Type: Extrusion

Year: 2021

Dimensions (l x w x h): 1100 x 700 x 500 min 1300 max

Mass: 285 kg

Heating

Power supply: Three-phase electric - 380V

Heating element type: Cartridge Heater

Number of heating elements: 64

Heating power: 10600 W

Operating temperature: 0 to 250 °C

User Process

Materials processed: Soft plastic, Hard plastic

Filling Method: Extrusion

Construction

Construction materials: Steel Frame, Aluminum Body

Material Cost (EU): 7500 Euro

Manufacturing time : ± 5 Days

Workforce: 1 Person

Difficulty ★ ★ ★ ☆ ☆

Connections

Electrical: Three phase plug socket 16 A

Pneumatic: Compressed air for cleaning